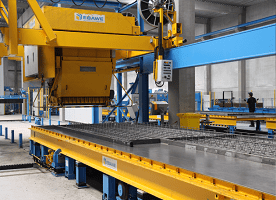

Quality

Precast technology, by virtue of the industrial process involvement of casting under controlled ircumstances, adheres to the highest standards of quality control.

Speed and Strength

Precast concrete construction does jobs sooner. Depending on size and site conditions, flooring for a number of units can be laid in a single day. Use of higher grade concrete and steel than conventional makes it tructurally superior.

Long Life and Low maintenance

Research has proven that precast elements can ensure more than a 100 year life cycle which reduces the life cycle cost of projects. Precast technology assures uniform quality and eliminates leakage and cracks thereby reducing maintenance costs.

Cost Effective

Early possession, slabs and beams with longer spans at lower depths, lower structure weight, efficient use of resources with minimal wastage and shorter timelines, all contribute to an economic solution.

Weather and Fire resistant

Precast concrete is an all-weather construction material, equally effective in regions with freezing or corching temperatures. It is also non-combustible and does not melt, eliminating the need for additional fire proofing works.

Energy efficient

Prestressed concrete components can improve the thermal storage potential of a building. It effectively onserves energy required for heating and cooling.

Clean and Safe

No shuttering, scaffolding, material procurement and inventory needed on-site. Clutter free and safer site

Long spans

Prestressing allows for casting elements longer than those achievable by conventional systems. A typical 300 mm Hollow core Slab can span up to 16 m and T slabs up to 22m without intermediate columns and beams.

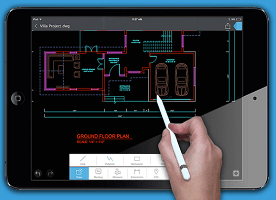

Design

Precast provides a structural platform which will give the architects and structural engineers greater freedom in designing virtually any layout.

Performance

High thermal mass of Precast combined with sound insulation reduces noise and provides an effective sound barrier between roads and urban noises.